- Jiangsu

- + 86 13605261217

- saleslucy001@gmail.com

For over 20 years, HAAPY has been dedicated to providing superior solutions for textile companies worldwide. Our equipment is more than just machinery; it’s a powerful engine for improving production efficiency, reducing energy costs, and achieving green manufacturing. Choosing HAAPY means choosing a future of stability, efficiency, and environmental responsibility.

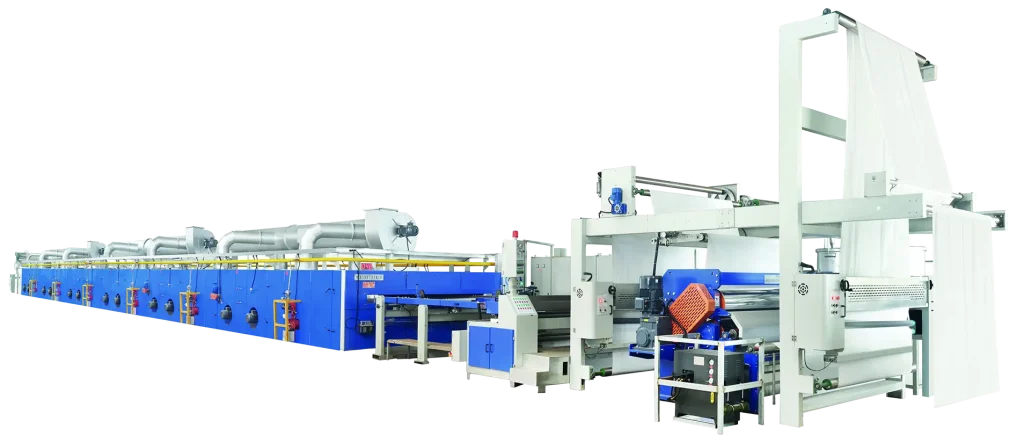

High-precision temperature control system with uniform hot air circulation ensures dimensional stability and superior hand feel of fabrics.

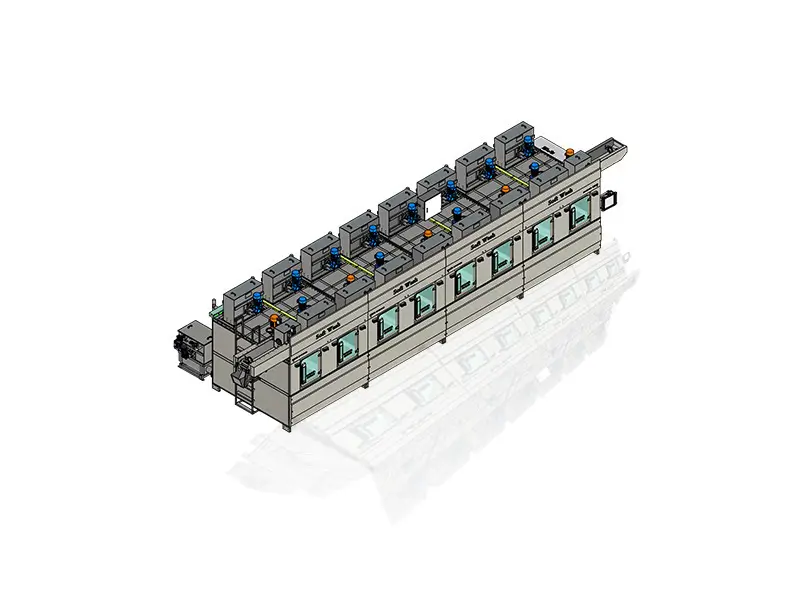

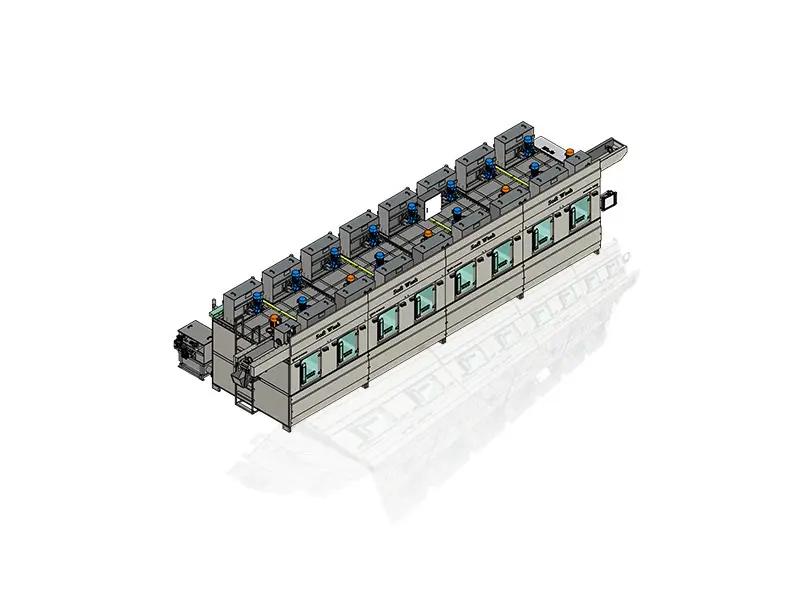

High-efficiency dip-coating equipment ensures uniform chemical penetration, automated application and even distribution

Low-tension drying process that preserves the fabric’s natural hand-feel, suitable for a wide range of knitted and woven fabrics.

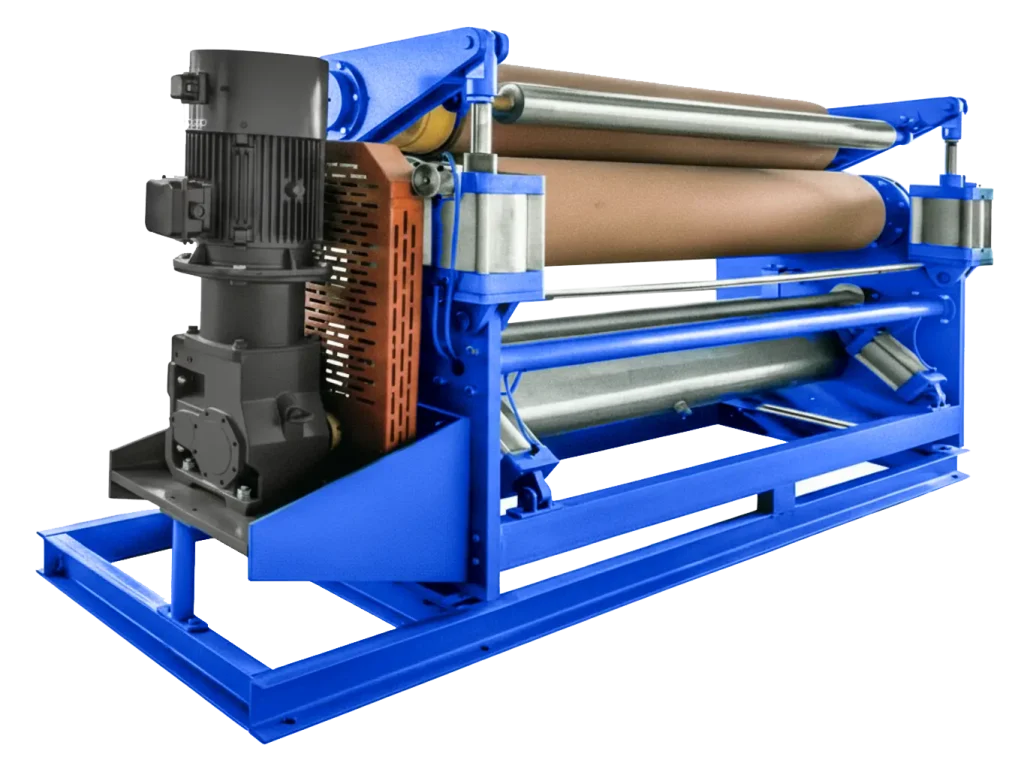

2-7 roll calendering system, improves fabric luster and smoothness, increases product added-value.

High-Efficiency Padding Equipment, ensures uniform chemical penetration, with automatic application and even distribution.

Turnkey production lines with full integration and support Get Custom Quote

Based in Jingjiang, Jiangsu—the heart of China’s textile industry—we combine German precision manufacturing with expert Chinese textile craftsmanship to deliver world-class production solutions. augue neque gravida in fermentum sollicitudin.

We provide customized smart textile machinery solutions tailored to the unique needs of our clients.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We provide comprehensive end-to-end solutions by deeply understanding client requirements, combining industry trends with technological innovations to deliver optimal machinery selection and process enhancement strategies.

Our R&D team consistently develops cutting-edge products and breakthrough technologies based on market evolution and industry demands. We maintain an extensive portfolio of invention and utility model patents.

With over three decades of specialized expertise in textile machinery manufacturing, we continuously refine our product designs and production methodologies to enhance equipment adaptability and reliability.

We utilize advanced testing equipment and professional engineering teams to conduct thorough performance evaluations on all machinery, ensuring exceptional operational performance and long-term stability.

Our worldwide support network ensures 24/7 technical assistance and rapid response times. We provide multilingual support and local service partnerships across 30+ countries for seamless operations.

Our intelligent textile machinery delivers outstanding performance with energy efficiency, labor optimization, ultra-quiet operation, minimal maintenance requirements, eco-friendly design, and compact space utilization across all textile applications.

Choose us for cutting-edge textile machinery and a reliable partner who understands the market and ensures mutual success.

Initial Consultation

Understand your requirements and objectives

Solution Customisation

Provide tailored solutions and quotations based

Contract Execution

Confirm service details and sign the cooperation agreement

Project Implementation

Initiate project according to plan, with regular

Deliverables and Evaluation

Submit final deliverables and conduct

We will contact you within 1 working day, please pay attention to the email with the suffix “@gmail.com”.